Metro C: Galleries

From the Heart of Rome to the Surface

The underground route of Line C consists of two adjacent single-track circular tunnels with a useful inner diameter of 5.80 m.

These tunnels are located at a depth ranging from 20 to 50 meters below street level and were primarily constructed using mechanized excavation, with the use of 4 Tunnel Boring Machines (TBMs).

The tunnels constructed up to this point along the entire route of Metro C, particularly in the MonteCompatri/Pantano – Venezia (excluding) section, have a total length of approximately 24 km (of which 23.5 km were constructed using mechanized excavation and approximately 1 km using traditional excavation).

Mechanized Excavation

Mechanized excavation of the tunnels is carried out through the use of Tunnel Boring Machines (TBMs), which are the most technologically advanced machines for tunnel excavation in urban environments.

As the TBMs advance through the ground, they are capable of performing and lining the excavation. After their passage, the tunnel is fully lined and ready to be equipped with the installation of the track and the essential technological systems required for the control and management of rail traffic.

The excavation of the operational tunnels for Line C was completed in June 2011 for the Giardinetti–San Giovanni section (the underground part of the route from the Monte Compatri/Pantano terminus to San Giovanni). The 4 TBMs used achieved a total advancement of approximately 19 km (9.5 km in each direction) in the two tunnels.

The line tunnels, from San Giovanni to Piazza Venezia, were completed in August 2020, with about 4.5 km of excavation, reaching a total length of approximately 24 km.

Mechanized Excavation in Numbers:

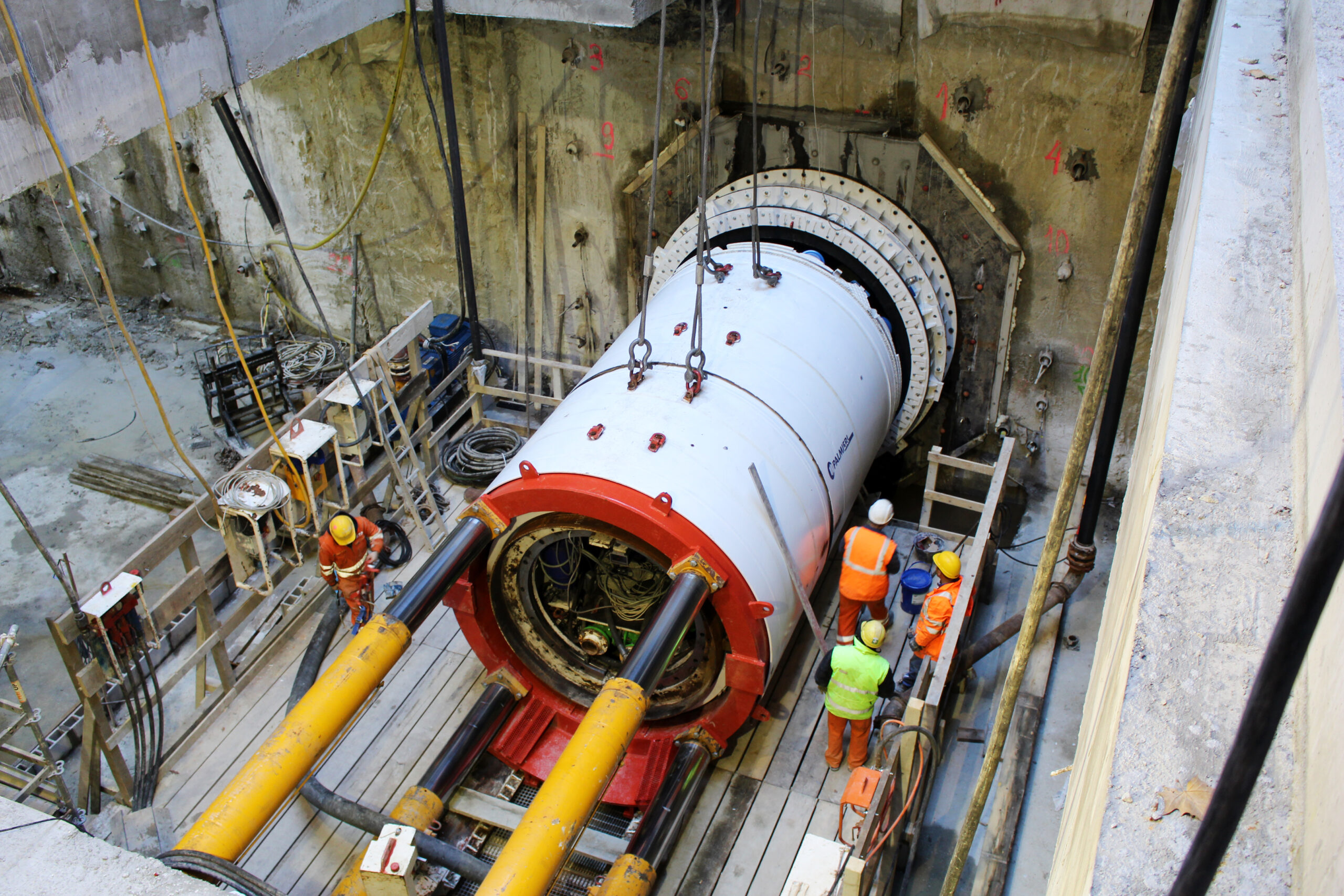

Tunnel Boring Machine (TBM)

Tunnel Boring Machines, commonly known as mechanical moles, are machines that, while excavating, assemble the tunnel lining. They have a circular cutting head protected by a shield and equipped with steel claws and rotating discs capable of breaking the soil.

The cutting head is connected to the machine body, which includes the driver’s cabin and systems, as well as the conveyor belt for removing the excavated material. Inside the shield, a system called the erector gradually installs the tunnel lining, which consists of segments. Segments are prefabricated concrete elements shaped like arches that, when assembled, form the support rings of the tunnel.

The TBMs used for Line C have a cutting head with a diameter of 6.7 meters, while the final tunnel lining consists of prefabricated segments that are 30 centimeters thick. Each lining ring consists of 6 main segments, along with a key segment. Each ring is 1.4 meters long and has an internal diameter of 5.8 meters.

The production of a TBM takes approximately 10 months. Once the individual components are transported to the site, they are assembled at the excavation site over a period of two months and then lowered into the underground through vertical shafts. These shafts are also used to transport excavated material to the surface.

TBM Segments Reinforced with Steel Fibers

Among the main innovations introduced in the Line C project, it is worth mentioning the use, for the first time in Italy, of prefabricated final linings installed within the mechanized excavations, reinforced with steel fibers embedded in the cementitious matrix, replacing conventional reinforcing bars. This system was developed for the construction of the final section of the line’s tunnels up to the Venezia station, consisting of approximately 70 rings with a length of 140 cm, in order to expedite the tunnel construction compared to the perimeter diaphragm walls of the station.

On October 2, 2019, Metro C S.c.p.A., in collaboration with the precast concrete company Italia, obtained, for the first time, the Technical Assessment Certificate – in accordance with Chapter 11, point 11.1, letter C of DM 17.01.2018 – for the use of concrete reinforced with metallic fibers, useful for the construction of prefabricated structures and the lining of underground works. This system can be extended to the tunnels in the historic center, offering evident benefits in terms of durability, fire resistance, and structural passivation from stray currents.

Compensation Grouting

Compensation Grouting involves the injection of cementitious mixtures into the ground, to be used simultaneously with activities that may induce settlements, such as tunnel excavation.

In the case of Line C, Compensation Grouting was used to support the foundations of the Aurelian Walls, in order to compensate for possible settlements induced by the excavation of the subway tunnels. This technique was carried out starting from a temporary shaft, specially constructed in the gardens of Largo dell’Amba Aradam, with a clear internal diameter of 8 meters and an excavation depth of approximately 20 meters from the ground level. The consolidated surface through cement injections beneath the so-called “foundation level” of the Walls covers an area of 3,600 square meters. The technologies adopted for this type of intervention are considered cutting-edge due to the use of guided drilling, which reached distances between 40 meters and 70 meters.

Throughout all stages of the work, an extremely precise monitoring system was installed on the ancient structures to ensure the success of the intervention. An example is the use of leveling cups, which allowed real-time monitoring of the deformation response and the proper adjustment of the injection quantities. Prior to the intervention, a field test was conducted to verify the quality of the consolidation mixtures and the deformation response of the ground on a real scale.

From a technical perspective, the Compensation Grouting intervention allowed shaping the “subsidence basin” induced by the excavation of the TBM tunnels, limiting settlements and distortions on the foundation plane of the Walls to values compatible with their preservation.

Traditional Excavation

The Line C project includes the construction of limited sections of the subway tunnels using traditional excavation methods.

This methodology, applied beneath important hydraulic structures, has been designed for the construction of rail connections and platform tunnels when they are not contained within the station structure.

Generally, after the excavation using TBM, soil consolidation is carried out around the tunnel lining to improve strength characteristics and reduce permeability of the soil to minimize water infiltration into the tunnel during excavation operations.

The traditional excavation technology was used for a total length of approximately 1.4 km to construct the platforms of 6 stations (Torre Spaccata, Torre Maura, Alessandrino, Parco di Centocelle, Mirti, Colosseo – Fori Imperiali), the storage sidings at Malatesta and Alessandrino, the railway connections at Alessandrino, Pozzo 3.3 (located in the gardens of Via Sannio), and Pozzo 3.2 (located in the gardens of Piazza Celimontana), as well as for the excavation of the subway tunnels between Pozzo 3.3 and San Giovanni station.

The enlargement excavations are always carried out through the prior execution of radial consolidations using cementitious, chemical, and nano-silicatic mixtures with front safety secured through glass resin elements and metallic anchoring around the perimeter. The usual technology for the installation of the temporary lining of the excavated cavity consists of laying metal ribs and spritz beton to support the excavation in the temporary configuration until the permanent reinforced concrete lining is constructed.

Traditional Excavation in Numbers

Soil Injections

Injections are a technique aimed at improving the mechanical characteristics (strength and deformability) and hydraulic characteristics (permeability) of porous soils and fractured or fissured rocks through impregnation and/or filling with cement or chemical mixtures.

These treatments are carried out by pressurized injection – up to 16-18 atmospheres – of suitable mixtures through perforations equipped with valved pipes. The mixtures are fluids (suspensions, solutions, emulsions) with evolving rheological properties, initially suitable for penetration into the porous or fractured medium, and subsequently reaching the characteristics suitable for the treatment’s purposes.

This technology is widely used for soil consolidation in the traditional excavation of underground galleries beneath the water table.

Jet Grouting

Jet grouting involves the injection of a high-pressure cement mixture into the ground – up to 600 atmospheres – through small nozzles. This is done to consolidate foundation soils by creating columns of predetermined diameter.

Current techniques involve breaking up the soil while simultaneously mixing it with a cement suspension or removing the finer component through air or water jetting.

This is also a widely used technology for soil consolidation in the traditional excavation of underground galleries and for the creation of bottom plugs below the water table.

Freezing

Freezing is a soil consolidation technique that involves creating a protective wall of frozen soil inside which tunnel excavation and lining construction operations are carried out.

Compared to traditional technologies, this technique provides greater safety in dealing with issues related to water infiltration or local collapses of the excavation surface.

The freezing technology is used to consolidate and waterproof the soil in the case of traditional excavation of underground galleries below the water table in loose soils.

In the case of Line C, the artificial freezing system of the soil was used for traditional excavation of the galleries in the underpass of the existing San Giovanni station of Line A, and it will be employed for the construction of the platform galleries at Venezia station and the even-odd railway connection upstream of this station.

The compressive strength of frozen soil varies depending on the type of soil and increases with temperature. The values commonly used generally range from -5°C to -20°C, corresponding to variable strength values (between 3 and 20 Megapascals).

The temporal phases of a freezing process are:

- the pre-treatment phase through injections of cement mixtures and/or micro-cements;

- the phase of artificial freezing of the soil using liquid nitrogen and/or brine;

- the phase of maintaining the freezing using liquid nitrogen and/or brine.

Microtunneling

The section of the subway tunnel between San Giovanni station and Multifunctional Shaft 3.3 in Via Sannio was constructed using blind hole traditional excavation, following soil consolidation around the tunnel profile using chemical and cement injections.

The construction of the tunnels begins with the excavation of a pilot hole approximately 140 meters long for each track, created using a microtunneler, a remote-controlled shield equipped with a rotating cutter with a diameter of 3000 mm and an internal ring diameter (made of prefabricated reinforced concrete) of 2600 mm.

This technology allows the tunnel to be constructed by advancing the cutting shield guided by a laser system and propelled by hydraulic jacks.

The pilot hole created in this way is completely demolished during subsequent excavation operations to allow for the construction of the final larger-diameter tunnels. Once the pilot hole is created, radial consolidations are carried out from within this structure through injections of chemical and cement mixtures into the soil. These injections are necessary to improve the mechanical characteristics and impermeability of the soil before proceeding with the widening excavation of the two subway tunnels.